The path to AI: How manufacturers can drive out costs with automation

Learn about robotic process automation and artificial intelligence, and how they can help your manufacturing processes.

For manufacturers getting back to an operating rhythm, some truths are becoming clear. Cash is, of course, going to be important for some time to come. But we all know that cut too far, and the business suffers.

The focus, therefore, is efficiency and productivity.

Technology has always been a way to drive new efficiencies from plant and labour, so it’s no surprise that smart manufacturers are taking the opportunity of market disruption to put some of the latest technologies to work.

The reason?

To drive out cost and pave the way for the next generation of streamlined operations in the future.

One particularly strong line of enquiry is artificial intelligence (AI). For some sectors, AI promises truly revolutionary product development.

In pharmaceuticals, for example, we can expect it to be at the heart of personalised medicines.

In manufacturing, one of the most exciting aspects of AI is the exact opposite: we can start to put it to work in step-by-step, evolutionary ways, rather than going through yet more upheaval.

And that means some more acronyms…

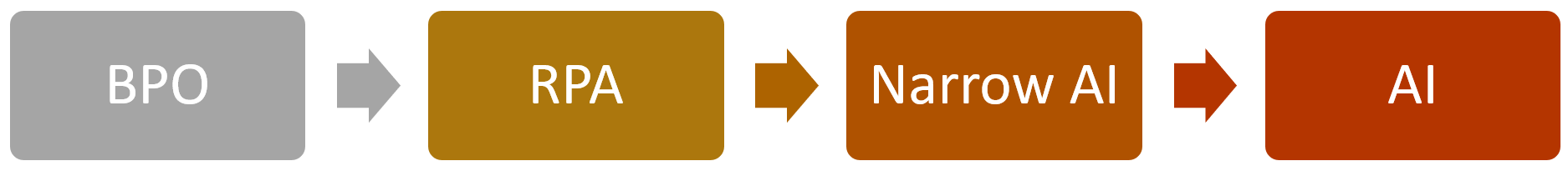

Four steps to automation

Step 1: BPO (business process optimisation)

Officially, this means trimming cost by shortening and refining processes.

In truth, for most businesses, it will mean looking at “the way we’ve done things round here for ages” and realising that many of those processes are outdated, unnecessary, or get worked around anyway.

BPO begins with an expert, manual reassessment of your regular activities – ideally by the people who actually do and/or manage those activities.

The Harvard Business Review says: “The existing business process is often overly complex, with unnecessary steps that could be eliminated before RPA [robotic process automation] is implemented.

“RPA involves the codification of business rules, but in many cases, business rules haven’t been examined for many years and don’t make sense in the current environment.”

Step 2: RPA (robotic process automation)

This leads us to RPA. With this, having mapped out and rationalised the processes that make up our business activities, many of them can be automated, either to reduce cost, or to deliver new value:

People are busy, so they become a bottleneck

We’re all used to the argument that computers make fewer mistakes than people. Yes, people are reasonably error prone. But, more importantly, when you’re looking for efficiency, people get busy.

When you can digitise a process, it ceases to end up ‘on someone’s desk’. And that means the cadence of business can continue uninterrupted.

The HBR again: “Existing business rules are sometimes described as requiring judgment, but in actuality they can be turned into more-accurate and more-consistent algorithms for better, more-consistent decision making.

“At a leading global logistics company, for example, the business rules in a claims process suggested that decisions on tolerances for refunds required the judgment of a manager.

“But when interviewed, the manager was able to clearly articulate rules of thumb he followed, which could be defined as rules for the RPA process to follow.”

Automation covers a range of tools

Today, automation can mean software widgets, integrations, or even physical robots.

Every manager should seek to automate anything that’s repetitive and/or low-value, whether it’s shifting values in Excel or moving boxes around a warehouse.

You might add processes, rather than taking them away

When a process can be automated, it might become economically viable, whereas when done manually, it is not.

Take, for example, sending a delivery update to a client. When this can be automated, the incremental cost of doing it is close to zero, while it adds huge value to the customer relationship.

Digital processes can improve a business, as well as removing cost.

You’ll now have a rationalised set of processes, aligned around the needs of the customer and the business, digitised wherever possible to reduce manual effort and cost.

Step 3: Narrow AI (artificial intelligence)

The next step is ‘Narrow’ or ‘Weak’ AI. Narrow AIs are designed to perform a single specific task, such as voice recognition and sorting items. They are increasingly available and economical.

AI allows those processes to be further automated by removing humans from increasingly complex sets of decisions.

An AI will take data from many different places in the business (such as production lines and order books) – which is why enterprise resource planning (ERP) will often be at the heart of AI data gathering – and optimise accordingly.

An AI, for example, might collate new orders, increase production to meet those orders, notify suppliers of the increased demand, and flag up any upcoming parts shortages.

To achieve this, AI needs data.

In the words of Thomas Boykin, a supply chain specialist leader at Deloitte: “Data is the life’s blood of the emerging digital supply chain.

“Companies that recognise the value of this data and engineer approaches to collect, filter and synthesize it into customer and market insights will flourish.”

If you have digitised processes where possible, you’ll have the data to hand (indeed many businesses find the opposite is the challenge: too much data). Either way, AI is about putting that data to work, to solve problems, refine operations and remove uncertainty end-to-end.

Analyst MHI reports: “Backward-looking analytics are now table stakes. Going forward, future supply chains will likely leverage data to feed predictive and prescriptive analytics that enable organisations to explore new possibilities, produce data-driven insights and bold decision-making, harness the power of disrupters, and generate breakthrough outcomes.

“Leading companies are reaping value from data by turning real-time sensor data into actionable insights through big data tools, cognitive analytics and machine learning.”

Step 4: AI

The ultimate goal is full AI: digital tools with skills approaching a human ability to assimilate information and make decisions.

Analysts disagree deeply as to when this sort of ability will be available and what it will look like.

In truth, the most likely mid-term outcome is augmentation. As robots will work side by side with humans on production lines, AI assistance will assimilate large amounts of data and make recommendations in order to help humans make better decisions, for which they retain ultimate responsibility.

The jury is definitely still out, but leading analysts IDC rightly point out that your initial investment doesn’t have to be high, and the value lies in your own information resources.

They say: “AI technology is being commoditised, which means that unless AI is your main business, you can simply use AI as a service provided by companies like Amazon, Google, and Microsoft or other niche players.

“Computing power is available via the cloud to almost any company. Machine/deep learning models and algorithms are open source and are being democratised…

“Data, particularly proprietary data, is an element on which your organisation can build a sustainable strategy for competitive advantage… Remember, your proprietary data is your competitive advantage. Protect it.”

A clear line to value

Of course, none of these advances come without a price tag of some sort (although most small and medium-sized enterprises will be able to make a start on assessing their processes without spending so much as a penny).

However, there has never been a better time to advance towards automation:

Coronavirus changed everything

As well as creating an incentive to develop modern, resilient systems, coronavirus (COVID-19) has taught us the value of digital insight.

IBM reports: “Using AI, organisations can turn unstructured real-time data into insights that help predict disruptions and vulnerabilities, providing near-term visibility… also understanding their up and downstream impacts, enabling more rapid response.”

Manufacturing is impressively placed to succeed

According to a November 2019 McKinsey survey, supply chain and manufacturing are two functions most likely to see cost savings as a result of using artificial intelligence.

It says: “The two functions in which the largest shares of respondents report cost decreases in individual AI use cases are manufacturing and supply chain management.

“In manufacturing, responses suggest some of the most significant savings come from optimising yield, energy, and throughput.

“In supply chain management, respondents are most likely to report savings from spend analytics and logistics-network optimisation.”

Automations and data are a virtuous circle

MHI again: “As global data volumes continue to grow exponentially, analytical computing capacity and tools are following suit – with innovations such as cloud computing and open source data analysis tools reducing the cost to both store and analyse the enormous volumes of new data.”

The cost of getting and using data is reducing, just as we are becoming better able to do more with it.

How to get started

If you’re interested in the path from BPO to AI, here are some steps to getting started:

- Examine your existing processes, through the lens of the people who live those processes every day. This will ensure that you solve real-world problems experienced by your teams and customers, rather than building tools that fail to serve the business.

- Develop pilot projects. BPO allows you to start small and demonstrate business value before spending on full AI solutions.

- Digitise processes wherever possible. Remember that with the right tools (such as connected systems and ERP), software will already make effective decisions in more circumstances than you think.

- Develop business cases with the whole enterprise. Operational efficiency demands different types of data than customer-facing sales and marketing applications. It will require insight from specialists across the company.

- Make AI easy. Like all technology implementations, adoption is driven by ease of use. When AI makes employees’ lives easier, it’ll be seamlessly adopted. If your new insights create barriers to day-to-day work, adoption will be much more challenging.

- Prioritise availability of data for the next generation of AI tools. The larger your datasets, the more successful your applications of AI will be.

Final thoughts

The development of AI is rapidly following that of other technology advances. Thanks to the cloud and modular solutions, the cost of AI (particularly pilot projects) is rapidly reducing.

Now is the ideal time to take calculated first steps – perhaps in one line of business or to solve a problem with clear constraints.

This will give you the initial experience to capitalise on AI as it becomes workable, and then essential, for businesses of any size.

Coronavirus and your business

We’ve gathered information and resources to help navigate this situation, including tools and webinars, to help you understand what financial support is available.