How Industry 4.0 will boost your manufacturing productivity

As a manufacturing leader, you have to focus on innovation and technology to improve the efficiency and performance of your businesses. You need to come up with strategies to make your organization relevant and competitive in an era where the digitization of manufacturing is a necessity.

Industry 4.0 is a major reason why digital business transformation has become so important. A vision of the interconnected factory, Industry 4.0 has changed manufacturing into a sector focused on connective devices and platforms that uses data gathered from the physical world.

The importance of Industry 4.0 to digital business transformation

Industry 4.0 connects embedded system production technology and smart production processes. It’s transformative to the manufacturing sector, as it allows you to better understand your processes, products and how their customers use them.

Industry 4.0 will allow you to collect real-time information across the entire supply chain, from suppliers to users, and analyze and use this data to improve and enhance your operation, designs, and products through instant feedback, thus improving manufacturing productivity.

Dr. Adrian Davis, EMEA Managing Director at (ISC)², says Industry 4.0 could grant you a range of business benefits, provided with an unimaginable level of detail.

“With a greater insight into their products, manufacturers can modify them to make them more attractive to prospective buyers and more useful to current customers, as well as designing them in a way that makes them less prone to errors and more safe and secure. Ultimately, it will enable manufacturers to better serve their customers and meet their expectations. Preparing for it now means staying ahead of the curve and ensuring competitors do not get the upper hand.” – Dr. Adrian Davis

Many leading enterprise manufacturers are already well underway in building cyber-physical systems – collaborating computational entities that are in intensive connection with the surrounding physical world and its ongoing processes, providing and using data-accessing and data-processing services on the internet. These include:

- IoT Sensors, which can allow physical devices such as vehicles to collect and exchange data.

- Big data and predictive analytics, which allow you to make sense of the huge amounts of information that your business can collect.

- Artificial intelligence (AI) and cognitive computing, which is the simulation of human thought processes in a computerized model, involving self-learning systems using data mining, pattern recognition, and natural language processing.

- Robotics, the branch of technology dealing with the design, construction, operation, and application of robots.

- 3D printing, or “additive manufacturing”, the process of making 3D objects from digital files.

Your manufacturing business must commit to digital business transformation

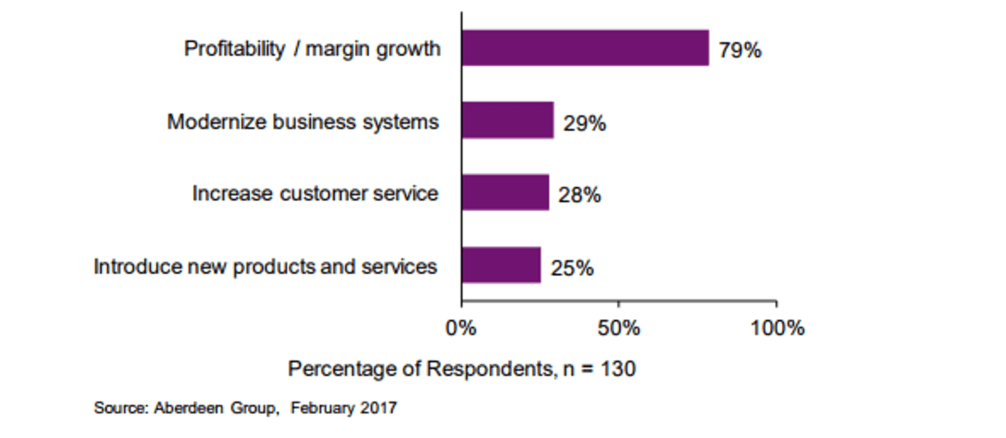

Before your business can think about exploring these new ways of delivering innovative products and services, it will be necessary for you to have changed your processes or even your business model. According to technology and solutions company the Aberdeen Group, modernizing business systems is second behind increasing profitability/margin growth as a top manufacturing goal.

The Aberdeen Group, says: “Products may need to customizable, requiring a change in the ways production and delivery are handled. Many of these changes would be impossible in existing business systems.”

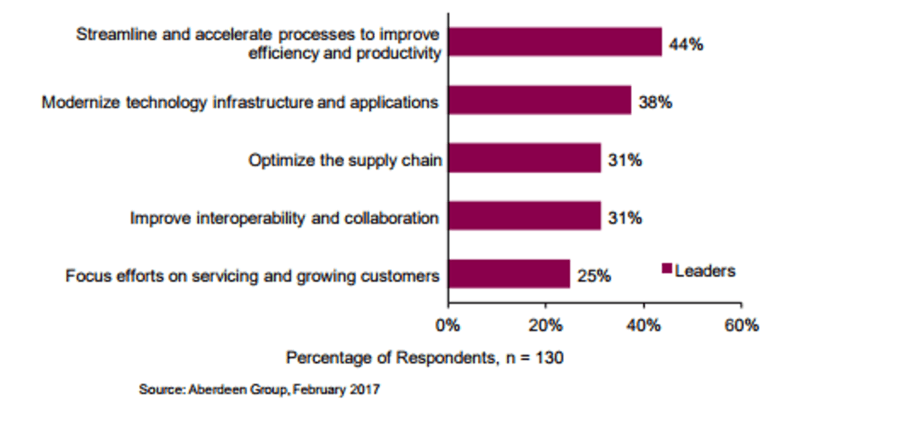

Also, consider that modernization is an integral part of part of the strategy for leading manufacturers:

To modernize and compete in the Industry 4.0 world, you will need initiate improvements across all operations, streamlining your processes to become more productive and improve collaboration across the business and supply chain. This is all with the aim of delivering the products and services that will grow your customers.

When approaching digital business transformation across the business, you should begin by thinking about your business model. For example, if you want to be able to provide ongoing service and after-sales support to build long-term relationships with the consumer, you need to think about the business and manufacturing processes you can bring in via new technology to offer this.

Adrian says: “A manufacturer of car brake pads would need to ask themselves whether they wanted just to manufacture brake pads or whether they also wanted to build relationships with car dealerships who will give them data on the pads’ ongoing performance.

“This kind of data would give them high-value information that would enable them to manufacture a more effective product.”

He warns that digital business transformation doesn’t happen overnight and should not be attempted all at once. He advises enterprises to begin by carrying out incremental trials it to see how it makes changes to the business or manufacturing process.

Mark Armstrong, is vice president and managing director of International Operations for EMEA and APJ at Progress, a global B2B application development company that works for brands such as Toyota, Coca-Cola, and more than 90% of the Fortune 500.

He believes that digital business transformation for Industry 4.0 must be built on solid foundations and driven by clear leadership from the C-suite. He advises your business to identify which technologies are most critical, and invest in those.

Mark adds: “It’s not just about investing in new technologies, it is about investing in the right ones. One thing is for sure though: Industry 4.0 is built on data. Manufacturers will have to retrofit equipment to collect data, learn to analyze it effectively, and use the insight to orchestrate future operations.

“To be Industry 4.0 ready, you will need to introduce systems that can automatically analyze large datasets into meaningful insights.”

Manufacturing Report: Riding the Wave of Uncertainty

How process manufacturers are planning for a brighter future in 2019.

How to use the cloud to support your digital business transformation

Industry 4.0 needs to have data accessible, connected and available to deliver the new processes and applications to improve your manufacturing business – which the cloud is perfectly set up for. One of the best ways to futureproof your business is to quickly scale up services – the cloud offers this scalability.

Adrian says you should look at the cloud as it provides massive data storage and ubiquitous connectivity, which you can connect to products to gain valuable insights, as well as connect to customers in offering additional support.

He says: “It offers a flexible and efficient way of conducting business which manufacturers should take advantage of, for example managing supply chains more efficiently, tracking inventories and components. The cloud will also create opportunities to connect suppliers, partners, and distributors together, allowing for better sharing of information and increased efficiencies.”

Christian McMahon, chief information officer of digital transformation consultancy three 25, advises you follow the examples of enterprises that have already turned to cloud computing platforms to accelerate their digital business transformation strategies, rather than sticking with long-established legacy systems.

He believes CIOs must learn to reject the fear of the unknown by embracing new technologies, with the aim of creating an architecture that supports the objectives of digital business transformation that delivers on performance without sacrificing security.

He says: “As part of this, they must listen to every area of the organization and its customers a lot more; people are asking for features and functionality that would dramatically improve the way they work, increase mobility and help the business gain a competitive advantage.

“These expectations are built on a consumer world available to everyone of highly customized, often updated services, and this allows them to assert pressure in their work environment.

“It means that they no longer just want ‘a new finance system’ or ‘a modern CRM platform,’ they want a bespoke solution that works quickly and seamlessly with their workflows, enabling them to be able to work more effectively from anywhere and deliver better results faster.”

Today firms such as Amazon, Microsoft, and Salesforce lead the pack in the provision of cloud infrastructure. Applications have become separated from infrastructure, which in turn has fuelled a proliferation of application developers.

Kieron McCann, director of strategy at marketing tech consultancy Cognifide, believes we could see a similar path emerge with Industry 4.0. The physical manufacturing capability could eventually become separated from intellectual property elements of product design.

He says: “This creates some interesting cloud manufacturing possibilities, where the physical manufacturing capability becomes available as a utility resource, either physically co-located or distributed. These manufacturing platforms become resources for any designer. The addition of 3D printing makes this quite feasible.”

Kent Eriksson is a senior digital business transformation adviser for PTC, a global provider of technology platforms and solutions that looks to transform how companies create, operate and build services with the Internet of Things.

He works with enterprise customers and partners to identify and evaluate new IoT business opportunities, develop programme roadmaps, and optimize business processes with IoT systems and tools.

He says: “Cloud can be public or private and is more an architecture choice depending on the implementation. Overall, it works well across companies and I believe we will see quite a lot of development of cloud-hosting technology going forward as, today, the hosting solutions are not all the same.

“The best way to take advantage is to build a roadmap starting with the current IT environment. Define a clear systems-of-engagement approach based on an innovation platform and move to the cloud at a pace that is cost efficient, has an acceptable risk and does not cause operational hiccups.

“By separating systems-of-engagement to the systems-of-records and systems-of-assets, the latter two can even be heterogeneous between sites. The approach also enables changes to both physical and digital assets or systems over time with less risk to operations.”

Prepare your business for the impact of AI

Kent believes AI is a natural evolution of Industry 4,0, where businesses are connected and data silos are being broken. For example, if an industrial machine breaks down, it cannot produce – and he believes businesses will be able to take advantage of anomaly detection through machine learning algorithms – useful for operating cycles which can be very complex.

Kent says: “Anomaly detection is quick, and often take just minutes. The machine continues to learn, improving over time and adapting to environmental changes. You can get notified if deviation happens – a person will still need to check, but this technology can likely prevent many costly breakdowns.”

“With AI, you should also understand predictive maintenance – where machine learning provides information on how to long it should before a breakdown is expected and what type it is, allowing a service technician to bring the right equipment. Machine learning may also be available to optimize service planning based on urgency and resource ability.”

In the future, machine learning could mean zero unplanned downtime. For example, prescriptive analytics could see AI systems ordering spare parts, optimizing inventory levels for consumables, shortening lead and execution times, and advising or performing actions that are needed. The higher you go on data aggregation; the more valuable advice AI could provide.

Kent says: “I think our imagination is the only limit to what’s possible – the challenge is putting the support in place. I’m a believer in not neglecting the simple. Anomaly detection is quick to deploy, and the first step for predictive maintenance – a natural step in AI evolution.”

Five digital business transformation tips

Digital business transformation is by no means a straightforward process – after all, it should mean a reinvention of business operations to benefit from technology. It won’t be straightforward and no two digital business transformation projects will be the same. However, there are some general tips to follow:

1. Build a dream team

It’s important for your whole C-suite to engage with digital business transformation, along with legal counsel and procurement executives. All involved should be aware of each other’s needs and priorities and focused on moving the business forward.

Different lines-of-business leaders will have different priorities when it comes to digital business transformation. It may help to bring them together in a workshop setting, but make sure it’s remembered that the priority is the health and ongoing success of the business.

Ideally, a high-level leader in your business should be identified to take on responsibility for the digital business transformation project, balancing the requirements of employees, departments and of course shareholders. And if there appears to be a skills gap, fill it.

2. Have a shared vision

Although digital business transformation will be met through a series of projects or initiatives, there needs to be a shared, desired vision of what your organization is trying to do and how it wants to get there – it’s a fundamental change.

Successful digital business transformation affects every element of an organization, which means every department and its employees must be engaged and included in the process. Your HR department will have an important part to play because staff will need to adapt to workplace changes.

3. Create a culture of collaboration

For some companies, the digital business transformation could mean the difference between competing and collapsing, but it should be remembered that it is not all about technology – businesses can’t become more efficient, productive and innovative unless these three things are embedded into their culture.

There must also be trust and partnership between different departments, with shared cross-functional goals and teams. You can build collaboration by finding a way of getting people from separate parts of the business working side by side and understanding each other’s challenges and capabilities.

4. Think data and innovation

Digital business transformation is not possible without data, which enables new technology and solutions. Data is where a business can gain those important, actionable business insights that make innovation useful.

This might need the absorption of new skills through recruitment, or training for the existing workforce. There is now a need for people to become quantitative thinkers where measurement is important, but only when the data analyzed can drive action.

5. Don’t be afraid to experiment

Every business is different – digital business transformation will come in many flavors, depending on short and long-term needs. Instead of thinking about the home run, businesses are better off thinking about small initiatives where feedback can be quick.

Make sure to experiment and evaluate with a business lens. And remember that digital business transformation is a process that doesn’t end – businesses will ideally have the technical flexibility to cope with what the world throws at them.

Ask the author a question or share your advice